Effectiveness Additionally Flexibility in New Approach of Engineering Polymer Brush Designs

Antimicrobial reducing boards. Flame-retardant carpets. Friction-resistant bearings. Engineered surfaces insert price to the issues we use, delivering additional levels of basic safety, easing their procedure, preserving their top quality or including utility.

At UC Santa Barbara, components scientists are hunting to tremendously boost on the notion with a technique of micron-scale floor chemical patterning that can not only reduce time and funds put in in their manufacture, but also insert flexibility to their layout. In a paper describing a technique known as “sequential end-circulation photopatterning,” UCSB components experts explain a new system for functionalizing and engineering surfaces with patterned polymer brushes.

“It’s a truly strong resource you can use for several functions,” explained Christian Pester, a postdoctoral researcher in the Craig Hawker Lab at UCSB. He is the guide creator of the paper, which seems in the journal Innovative Supplies.

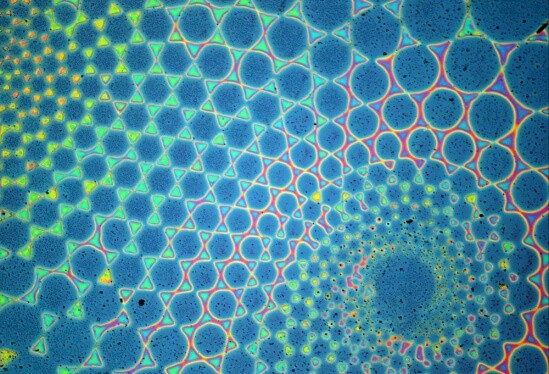

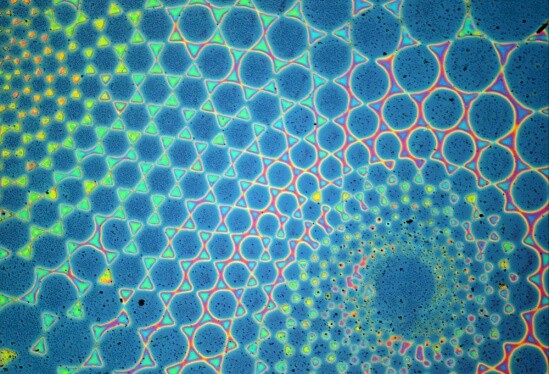

If you consider a near search at some engineered surfaces, you are going to see that at the micro- and nanoscale, they are not flat and vacant, but relatively consist of infinitesimal elongated polymer molecules hooked up at a single conclude to the floor. These polymer brushes imbue the floor with numerous houses and capabilities. They can, for occasion, repel drinking water, stop micro organism from attaching, boost drug supply or appeal to other molecules. Patterning polymer brushes enables the blend of a number of functionalities.

Typical approaches of patterning polymer brushes on surfaces are frequently repetitive and time-consuming, Pester explained. For a lot more than a single brush, the initial polymer development from an initiating “seed” have to be deactivated and the artificial approach recurring following re-depositing new initiating molecules. It can consider up to the greater element of a working day for each and every variety of polymer brush, he extra.

With sequential end-circulation photopatterning, the intermediate actions can be eradicated, Pester explained.

“It’s also chemically a lot more cleanse, since you are not iteratively depositing the initiator,” he explained, “which signifies you are also getting absent relevant washing and cleaning actions.”

To complete this feat, the substrate (with initiating molecules deposited) is enclosed in a end-circulation mobile and a resolution streamed in. Irradiation with light-weight can then initiate the response. A independent photomask — primarily a type of stencil — is positioned in excess of the prime of the mobile, hence making it possible for only some light-weight-activated development. Soon after the development action, the light-weight is turned off, the initial resolution is drained from the mobile and a next a single isflowed in to functionalize the polymers. Given that neither the mask nor the substrate has been moved, only the molecules that have been uncovered to light-weight are developed and functionalized. These simple actions could be recurring with variants in the reactants, the light-weight resource or the positions of the substrate or the photomask to produce polymer brush designs in a one steady approach.

“We can also produce chemical and peak gradients on the nanoscale,” Pester explained, characteristics that are only indirectly available with traditional approaches.

The engineering opens the doorway to enhanced flexibility in the growth of polymer brushes with an eye towards industrial purposes. Pester credits the collaborative character of UCSB study for this scientific growth, which is committed to the late Edward J. Kramer, components professor and founder of the campus’s Supplies Study Laboratory. “I believe what is truly great about this undertaking and I believe exactly where UCSB shines is in collaboration,” explained Pester.

Study on this paper was performed also by Kaila Mattson, Benjaporn Narupai, and Emre Discekici from UCSB’s departments of chemistry and biochemistry and of components. David Bothman from the Section of Mechanical Engineering and Kenneth Lee from the Section of Physics also contributed study, as did Daniel Klinger at the Institut Für Pharmazie, Freie Universität Berlin.